85%

Of pepper seed waste is currently discarded without being utilized for energy or value generation.

Pepper seeds are an underutilized agricultural byproduct with a surprisingly high oil potential. Instead of being discarded or burned as waste, these seeds can be converted into biodiesel without competing with food production. By focusing on pepper seed–based biodiesel, our project demonstrates how locally available waste streams can be transformed into a realistic, sustainable energy resource through small-scale, accessible technology.

Of pepper seed waste is currently discarded without being utilized for energy or value generation.

Potential greenhouse gas emissions avoided per liter of biodiesel produced from agricultural waste.

Biodiesel production modeled for prototype-level, decentralized use.

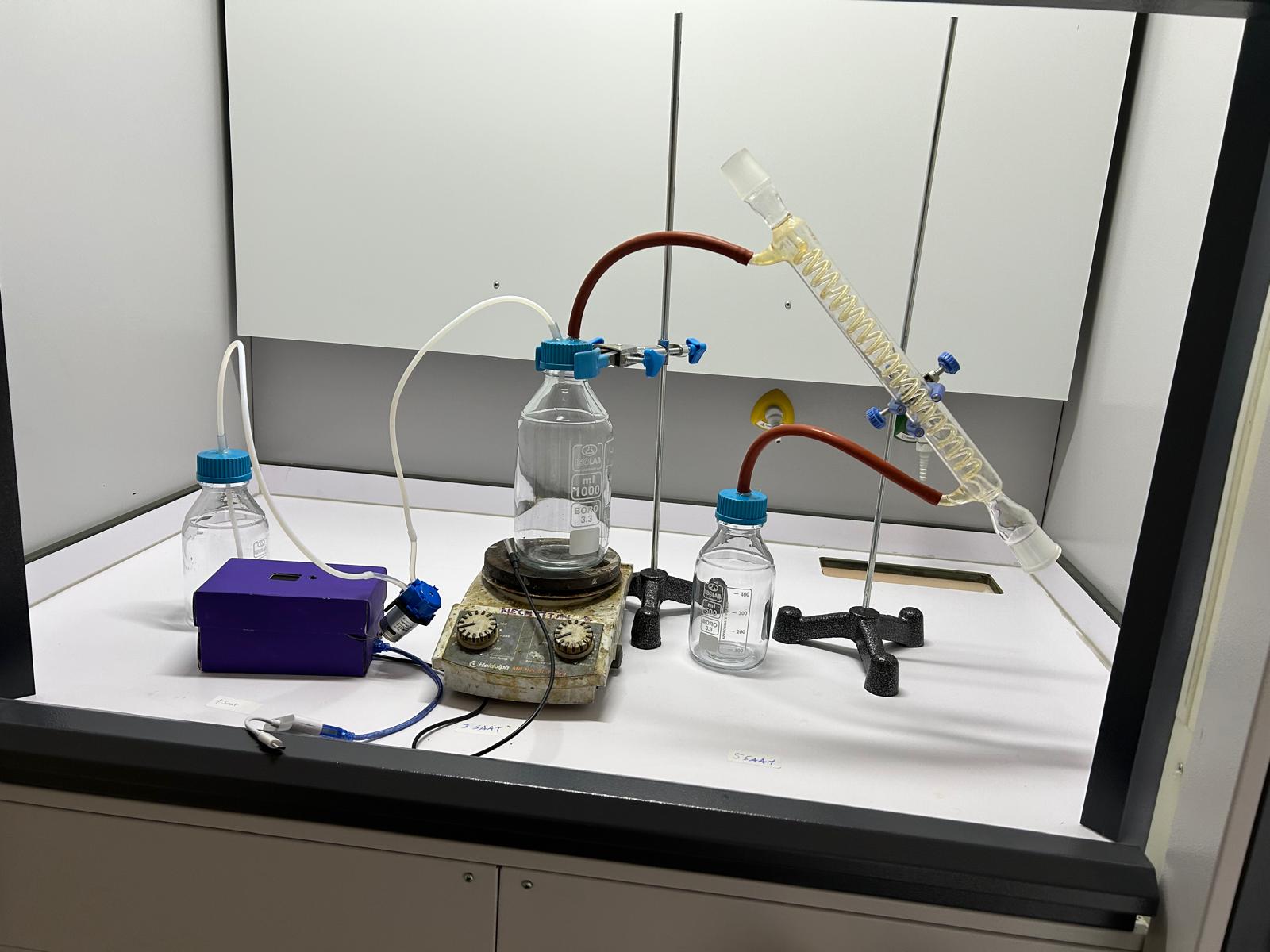

A physical system designed to validate simulation results in real-world conditions.

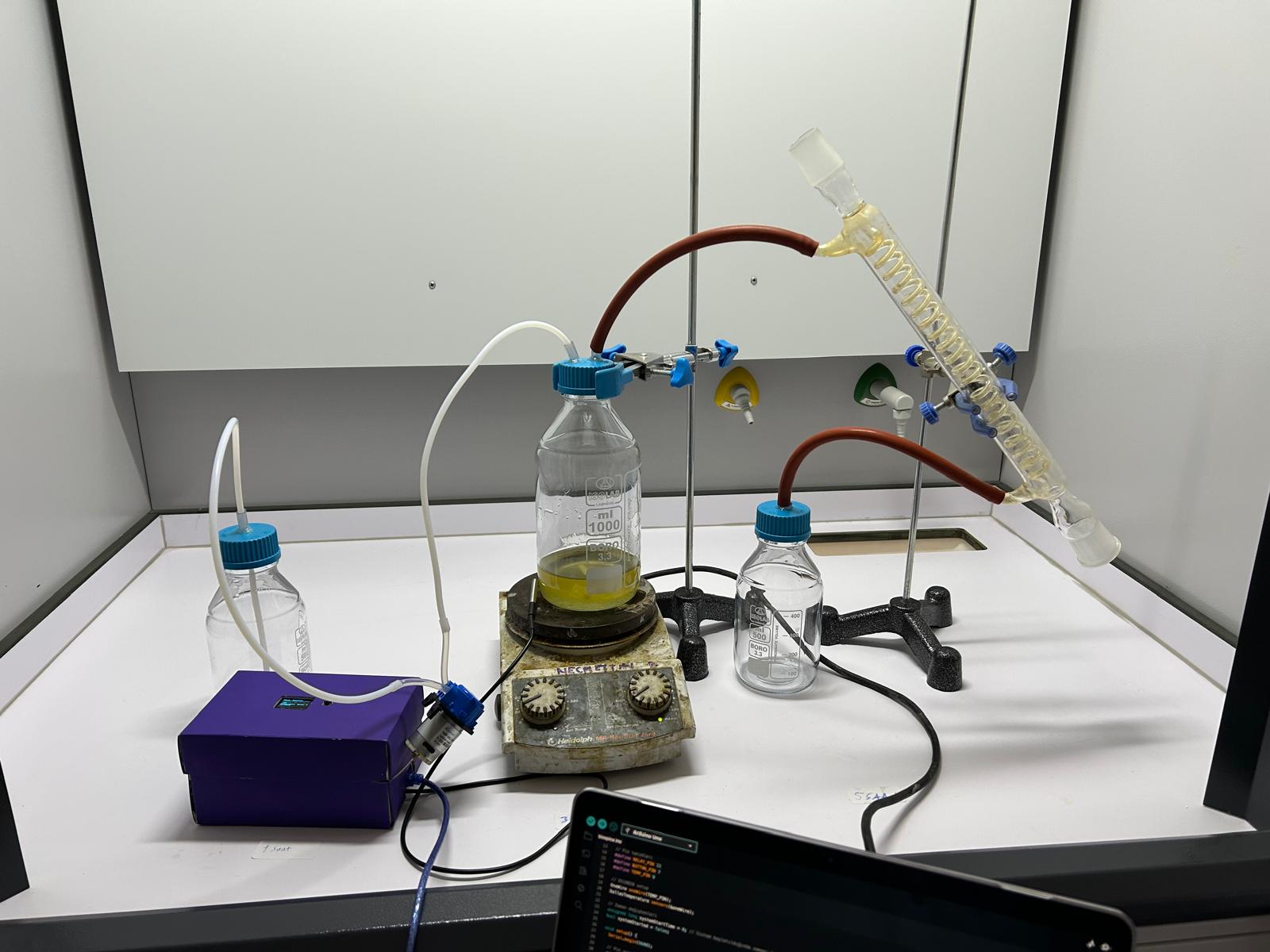

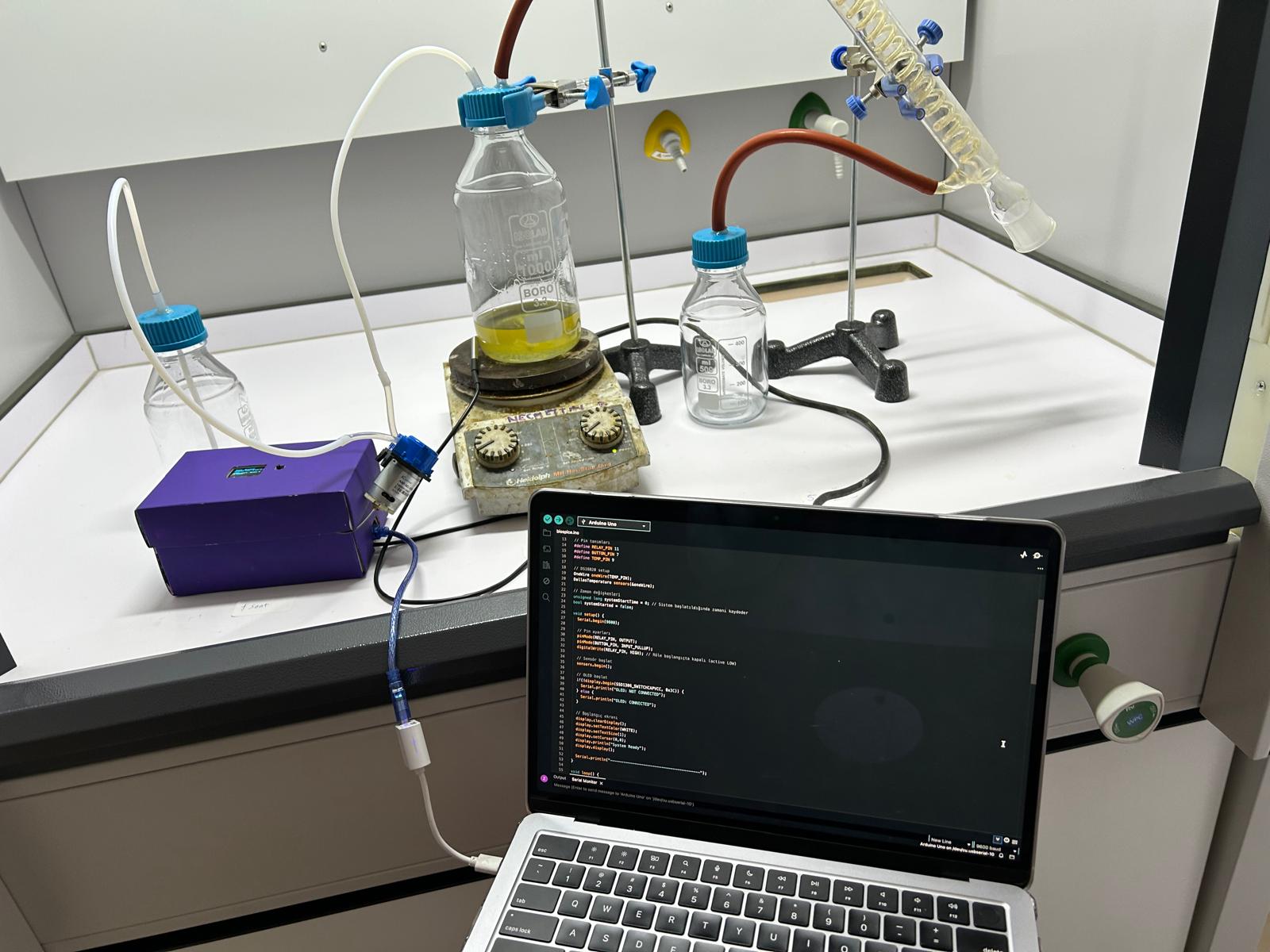

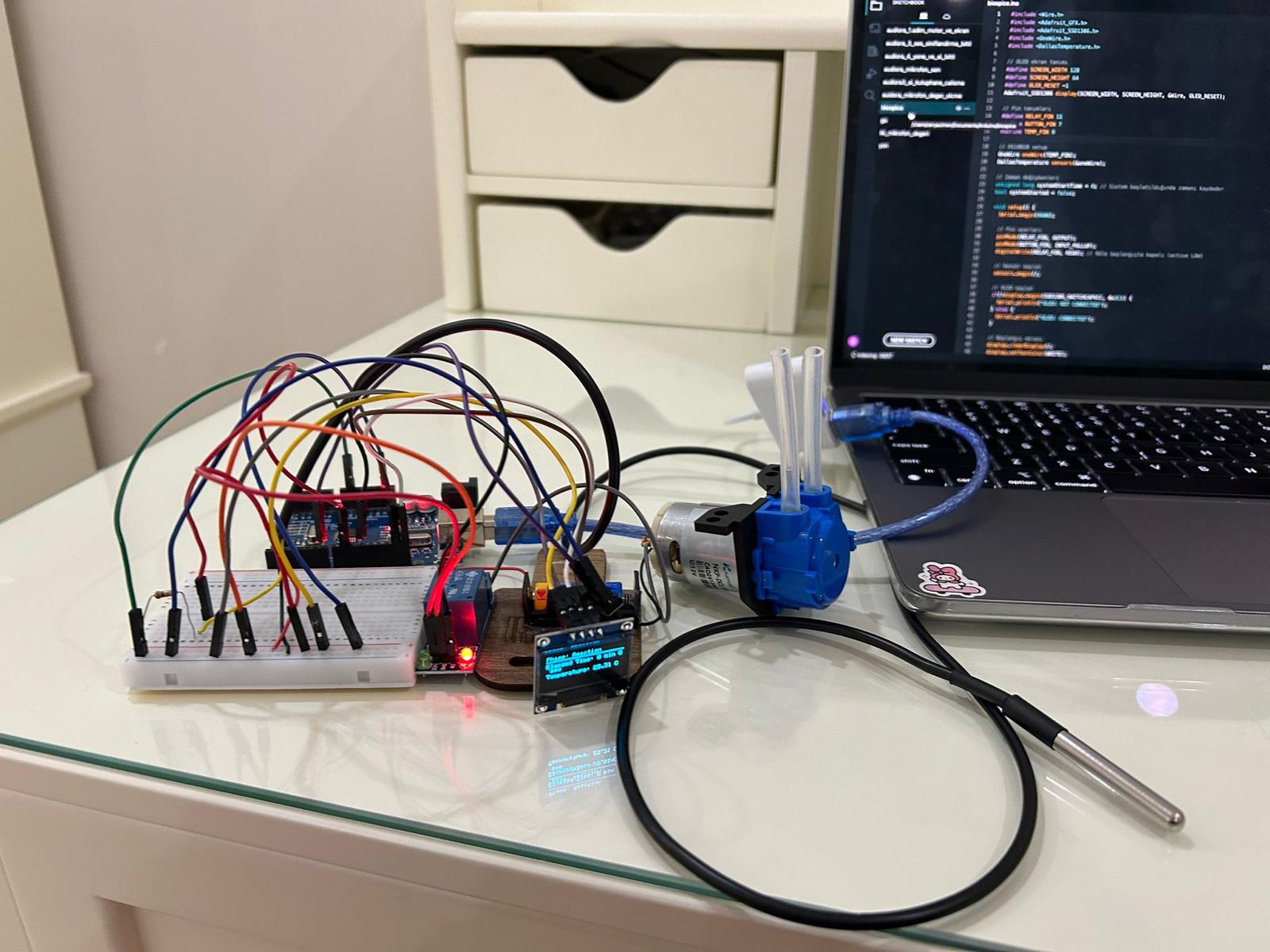

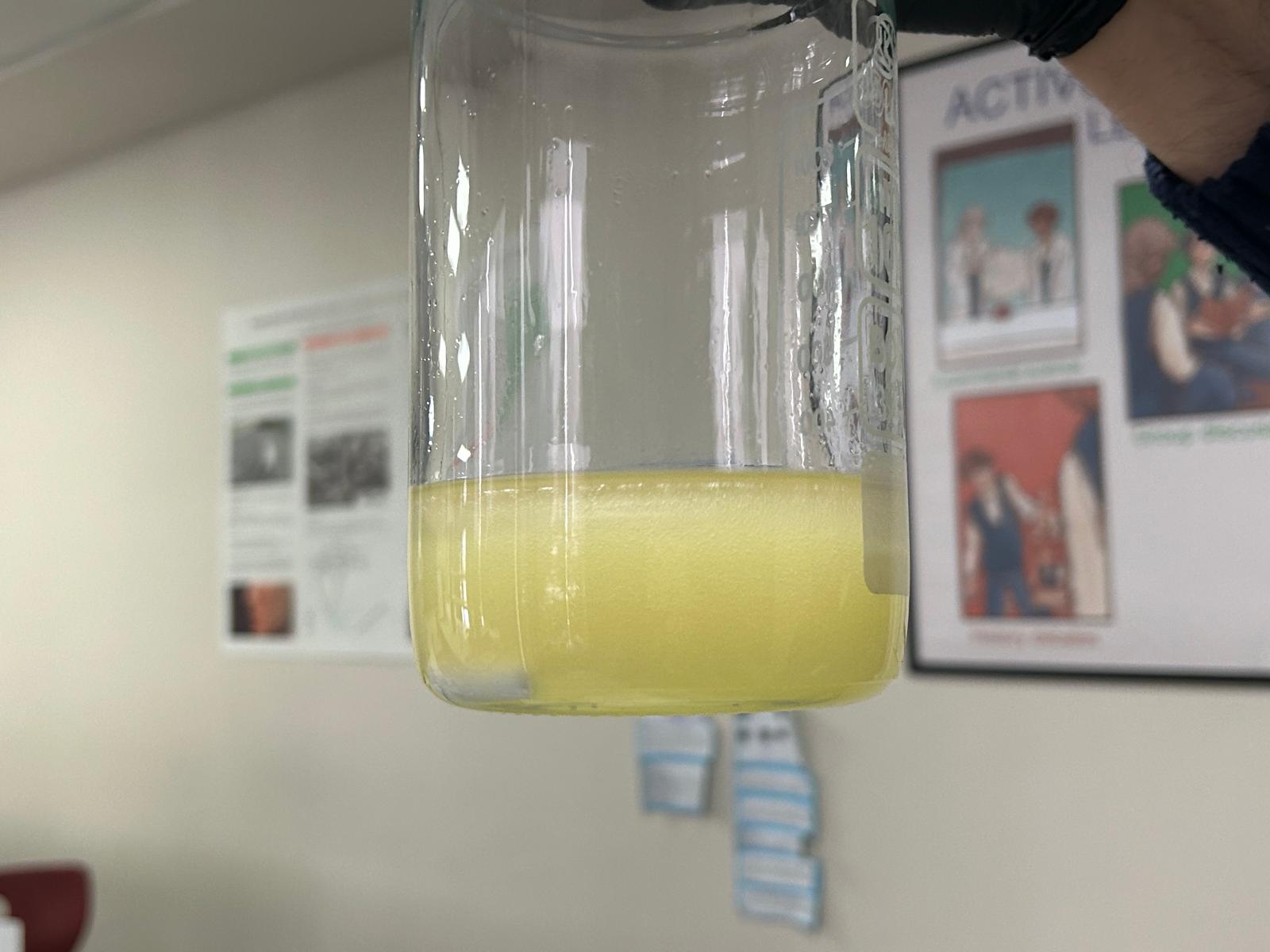

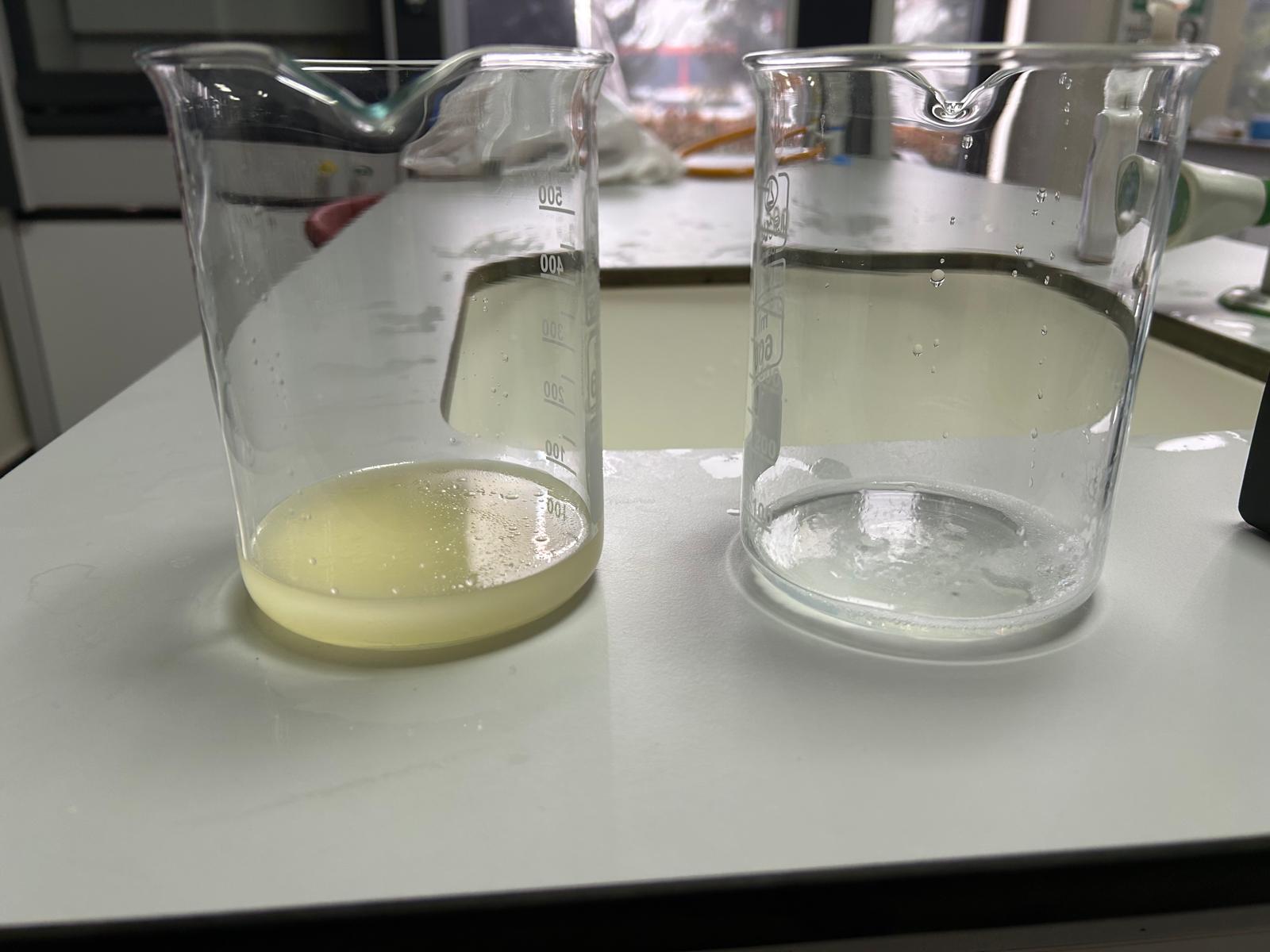

This section presents the experimental setup and key steps involved in building and testing the physical prototype, along with visual documentation of the results.

Our mission is to research biodiesel production and design a compact, prototype-scale biodiesel processing system that demonstrates how agricultural waste—specifically pepper seeds—can contribute to sustainable energy solutions.

This project investigates the biodiesel production process from end to end, combining experimental research, simulation, and prototype design. Pepper seeds are processed to extract oil, which is then converted into biodiesel through transesterification.

To bridge theory and practice, we designed a miniature biodiesel production device capable of processing small batches, allowing us to test feasibility, efficiency, and scalability in a controlled setting.

The simulation allows users to input parameters such as pepper seed availability, oil yield, conversion efficiency, and energy demand to estimate biodiesel output and performance.

By comparing biodiesel results with conventional diesel, the model highlights efficiency trade-offs, cost tendencies, and environmental impact, supporting informed decision-making.

Each component of the project is designed to balance scientific accuracy with practical usability.

Evaluate how agricultural waste can be converted into usable fuel.

Compare biodiesel and diesel in terms of efficiency and output.

Translate numerical results into clear sustainability insights.

Simple inputs ensure accessibility for educational and cooperative use.

Our approach combines literature research, experimental design, simulation modeling, and prototype development to ensure realistic and testable outcomes.

The simulation uses established biodiesel conversion data, oil extraction efficiencies, and energy content values drawn from academic research.

Variables such as feedstock quality, processing efficiency, and scale can be modified to reflect different scenarios.

Simulation assumptions are supported and refined through hands-on testing with the biodiesel production device.

Studying biodiesel chemistry and small-scale processing methods.

Designing and assembling a compact biodiesel production prototype.

Producing biodiesel in small batches to validate efficiency and feasibility.

Demonstrating how the model could be adapted for larger or community-level use.

Have questions about the project or its applications? These answers address the most common points of interest.

Yes. The system processes pepper seeds in small batches, converting extracted oil into biodiesel for analysis.

The current design is optimized for prototyping, but the process can be adapted to cooperative-scale production with further engineering.

The simulation uses peer-reviewed data and validated assumptions, with outputs refined through prototype testing.

The simulation and prototype are based on established biodiesel production principles, including oil extraction, transesterification efficiency, and fuel energy content. While the project demonstrates feasibility and impact at a small scale, real-world results may vary depending on feedstock quality, processing conditions, and scale of operation.