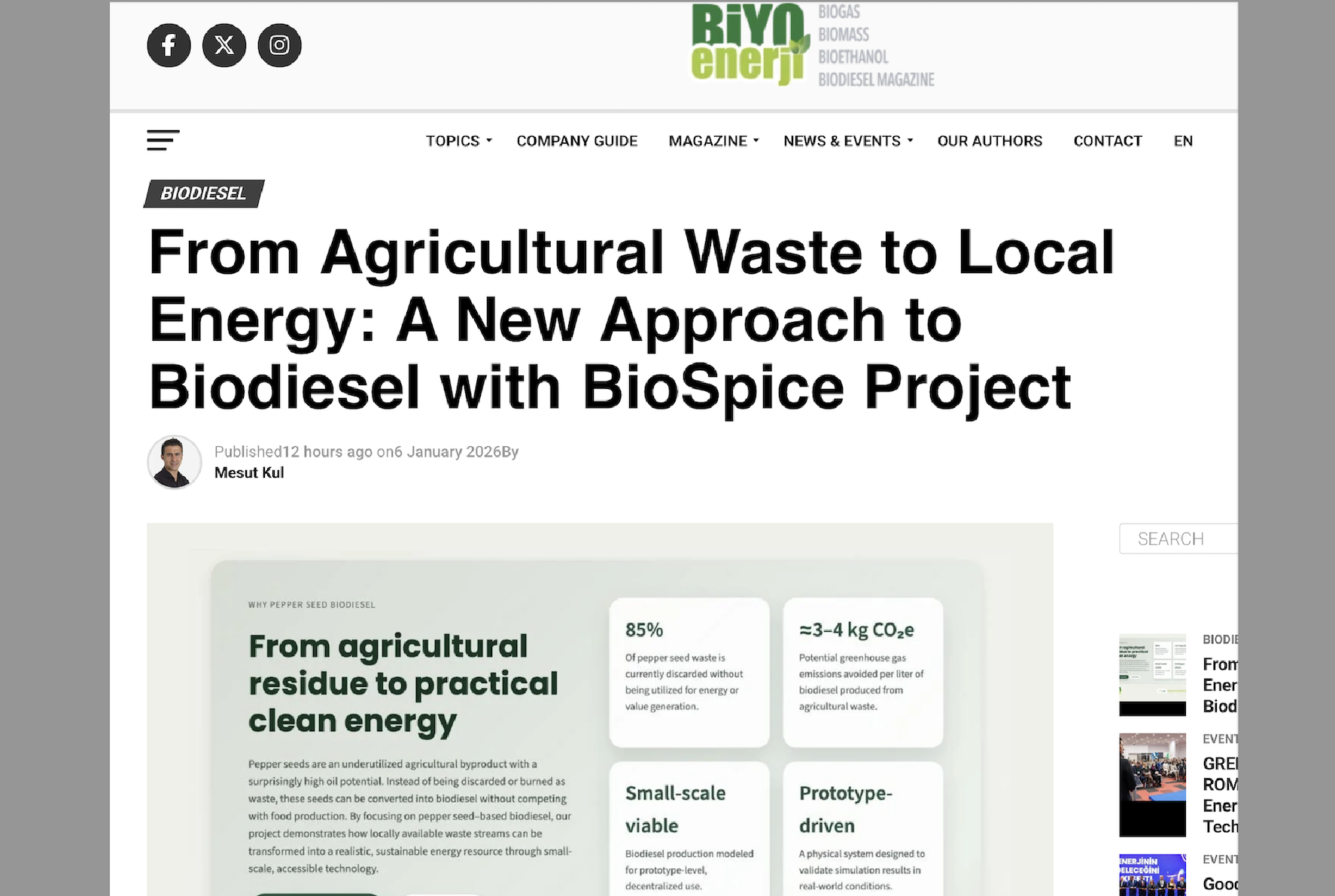

Waste-based feedstock

Pepper seeds recovered from agricultural waste streams, requiring no additional land or food resources.

Explore visual notes and photos from the simulation build, lab trials, and cooperative outreach.

This project integrates a biodiesel simulation with a functional prototype to connect theory with practice. While the simulation models oil yield, conversion efficiency, and fuel output, the prototype validates these assumptions experimentally.

By focusing on pepper seed waste, the project introduces a low-cost, waste-based biodiesel pathway suitable for small-scale and decentralized applications.

Pepper seed residues—typically discarded—are used as a biodiesel feedstock. With an oil yield of 0.25–0.28 L per kg of seeds, this waste stream becomes a measurable energy resource.

The simulation incorporates experimental and literature-based values, including oil extraction efficiency and 88–94% transesterification yield, ensuring realistic projections of biodiesel output.

Inputs are structured around real agricultural data such as seed availability and seasonal production, making the system relevant for cooperatives and local producers.

The project aims to show that biodiesel from pepper seed waste is not only environmentally beneficial but also economically meaningful at small scales.

Waste-based biodiesel reduces reliance on fossil diesel and lowers lifecycle emissions by repurposing agricultural residues.

With pepper seeds assumed at 0 TL feedstock cost, production cost is driven mainly by methanol and processing—resulting in lower TL/L fuel cost compared to market diesel.

Partnerships with local farmers enable waste collection, shared benefits, and increased awareness of circular energy systems.

We evaluated multiple biodiesel feedstocks and selected pepper seeds based on availability, oil content (25–28%), and sustainability.

We modeled biodiesel yield, fuel efficiency, methanol consumption, and production cost per liter using real conversion data and experimental ranges.

We designed and tested a miniature biodiesel production system to verify conversion efficiency, material losses, and feasibility under real conditions.

The contributions of our sponsors enabled the BioSpice Project to evolve from initial modeling into a validated, working prototype.

Local pepper producers provided real waste data, ensuring the simulation reflects realistic seed quantities and seasonal variability.

Prototype testing demonstrated that optimized reaction parameters can reduce methanol excess while maintaining high biodiesel yield.

Quantified results—oil yield, conversion efficiency, and cost per liter—strengthen discussions with sponsors, educators, and sustainability programs.

Enter your available pepper seed amount and discover how much fuel, distance, and savings are possible.

Start Simulation